Optical phased array (OPA) technology is an innovative approach to lidar that is rapidly emerging to meet performance and cost requirements for the autonomous vehice (AV) market. This exciting new lidar architecture is specifically designed for low-cost, high-volume, automotive-grade manufacturing. Learn how OPA-based lidar works, its advantages over traditional mechanical lidar, and why it is the technology to watch for autonomous vehicles.

Lidar enables the future of AVs—it is a key technology that will help make self-driving cars safe, efficient, and reliable. Until recently, however, the lidar market has been dominated by high-cost mechanical lidar sensors. While those costs are decreasing, most automotive lidar contenders simply cannot meet a <$500 per unit threshold and maintain the performance and reliability needed for consumer vehicles.

A next-generation technological approach to lidar leverages solid-state devices and OPA sensing technology to meet performance and cost requirements for the AV market. As OPA-based lidar continues to evolve and mature, it will emerge as a cost-effective, high-performing technology with advanced situational awareness for AV navigation and collision avoidance—that can be manufactured at scale. This target architecture of choice has been evidenced in the proliferation of automotive phased-array radar during the past two decades, as the industry has embraced phased-array architectures with shipment volumes of automotive radar already exceeding 20 million annually.

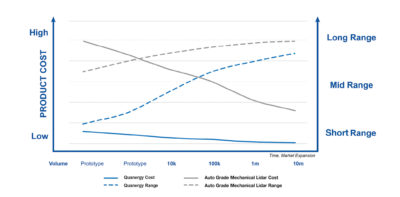

While OPA-based lidar is still relatively new compared to traditional mechanical lidar, it is making such rapid advances that solid-state lidar with OPA technology will begin to achieve relevancy to the transportation industry by 2022. Figure 1 explains Quanergy’s high-level architecture philosophy for automotive lidar. Although performance specifications are important, the most crucial aspects of lidar deployment in the transportation industry are low cost and high reliability.

A conscious architecture choice was made to use a silicon complementary metal-oxide semiconductor (Si CMOS) process for all critical components in OPA-based solid-state lidar. The motivation is to ride the mature semiconductor process to support a low-cost, high-volume manufacturing cost structure. Quanergy understood that this technology development path would be more challenging and time-consuming; however, the company pursued this route, eschewing any shortcuts that could compromise the long-term cost and reliability metrics—the ultimate determining factors for lidar democratization.

In this article, we explain what OPA is and why it is the technology of choice for autonomous vehicles.

The challenges of traditional mechanical lidar

Figure 1: Quanergy’s high-level architecture philosophy for automotive lidar hinges on a low-cost base technology platform. As the development takes its course, the detection-range performance increases and the cost further decreases with expanding applications and manufacturing scale.

3D lidar can be achieved with either solid-state scanning or mechanical motion. Despite many lidar vendors claiming solid-state capabilities, most lidar sensors on the market today operate using either micro- or macro-scale mechanical motion. These lidar sensors typically use either spinning or oscillating mechanisms, or MEMS (micro-electro-mechanical systems) mirrors, to achieve the mechanical scanning function.

While lidar sensors that operate with mechanical motion are used in some industries and applications, they have their limitations for the automotive market. For example, spinning or oscillating lidar sensors are relatively large and bulky to accommodate the scanning mechanisms. In addition, mechanical lidar sensors are more expensive to manufacture compared to newer types of lidar. Both factors make mechanical lidar impractical for widespread deployment in autonomous consumer vehicles.

Mechanical scanning also means there are many moving parts that are more likely to wear prematurely or become misaligned when exposed to shock or vibration. The mechanical scanning also limits the sensor’s ability to respond respond adaptively to rapidly changing situations—like driving. Considerable engineering effort is being invested to bring macro- or micro-mechanical lidars to automotive grade compliance.

What is OPA?

Figure 2: The principle of Quanergy smart zooming: an object, in this case a deer in the headlights, is detected in the coarse view (above), so the lidar sensor zooms in on this to provide the fine view (below), yet the system remains conscious of the broader field of view.

OPA is the optical analog of phased-array radar. A phased array has multiple antenna elements that are fed equal-intensity coherent signals and use variable phase or time-delay control at each element to generate an arbitrary far-field radiation pattern and sweep it in space.

Quanergy’s solid-state lidar1 uses OPAs fabricated using a CMOS-compatible silicon photonic integrated circuits (PICs) process. Laser beams are steered electronically, sweeping the view angle of the sensor with no moving parts. Solid-state lidar further reduces costs with a silicon CMOS detector solution, providing a path to commoditization for lidar sensors.

Common misconceptions about OPA

While OPA lidar technology may sound new, it is based on decades of research. Furthermore, the electronics and software solutions developed for the spinning lidar products are also applicable in solid-state lidar. This helps accelerate the pace of commercialization. As with any emerging technology, however, there remain important developments in OPA-based lidar that will continue to improve the technology and make it more broadly applicable and cost-effective in the coming years. For example, though the first commercial product was released into short-range flow-management applications, Quanergy’s OPA-based sensors are now rapidly extending their performance levels to higher scanning rates and longer detection ranges of 100 meters or more under outdoor conditions with bright sunlight and 10% reflectivity targets. This evolution is expected as the technology matures and positions OPA as not just a contender—but a winning solution—for the AV market.

While OPA lidar technology may sound new, it is based on decades of research. Furthermore, the electronics and software solutions developed for the spinning lidar products are also applicable in solid-state lidar. This helps accelerate the pace of commercialization. As with any emerging technology, however, there remain important developments in OPA-based lidar that will continue to improve the technology and make it more broadly applicable and cost-effective in the coming years. For example, though the first commercial product was released into short-range flow-management applications, Quanergy’s OPA-based sensors are now rapidly extending their performance levels to higher scanning rates and longer detection ranges of 100 meters or more under outdoor conditions with bright sunlight and 10% reflectivity targets. This evolution is expected as the technology matures and positions OPA as not just a contender—but a winning solution—for the AV market.

Unique capabilities enabled by OPA

OPA technology conveys many benefits that cannot be achieved by other methods of lidar scanning, including intelligent and adaptive situational awareness, high reliability for daily use in consumer vehicles, low-profile form factors that integrate seamlessly within the vehicle design, and low-cost production at high volumes.

As has been the case in many industries (for example, communications, computers, medical sensors), hardware is typically commoditized over time by semiconductor technology at one end and software technology at the other. The OPA architecture inherits both semiconductor cost trajectory and software scaling and follows this natural trend to enable scalable volume deployment.

Four of the advantages of OPA that are crucial to the AV market are explored further below.

1. Adaptive smart zoom

Electronic scanning enables a more adaptive approach to scanning and zooming into areas of interest. The sensor can adjust its laser beam movement dynamically depending on the changing environment. For example, Quanergy’s solid-state lidar sensors feature smart zooming, which can zoom in and out dynamically to provide coarse or fine view (Figure 2), without losing sight of the broader field of view. This software-controlled beam formation and steering brings intelligence into the sensor hardware and puts the beam precisely where the light is needed.

2. Unmatched reliability

OPA-based lidar is a true 100% solid-state lidar with zero moving parts. This provides immunity to shock and vibration, with over 100,000 hours of mean time between failure (MTBF). The unmatched reliability and longevity of these sensors makes them ideal for use in consumer vehicles.

3. Low-cost, high-volume production

Quanergy’s OPA-based solid-state lidar uses mature CMOS silicon production processes, which can support extremely high-volume production at scale for an exceptionally low cost compared to competing lidar sensors.

4. Seamless integration in vehicle design

The compact, lightweight OPA-based lidar sensors can be seamlessly integrated into the design of vehicles and provide rich data for object detection, tracking and classification, and the support of a variety of functions including truck platooning, ADAS functions (lane departure/change warnings and forward/reverse collision warnings), autonomous valet parking, and self-navigation in geo-fenced areas.

Conclusion

After many years of being perfected for lidar, OPA technology is quickly coming up to speed to intersect with the growing need for intelligent sensing in the automotive industry. It’s another way lidar is improving the quality of life for people around the world—and, ultimately, making our world a safer, better, more efficient place.

1 Currently the S Series products: https://quanergy.com/products/s3/.

2 Company website: www.quanergy.com.

Editor’s note: For more info, see: Energy at Quanergy: Markets Accelerate Beyond Automotive