Winter Garden, FL – January 21, 2021 Remote Operation is the keyword of our time, even applying itself to the mining industry. The VZ-i Series of 3D terrestrial laser scanners are ready to meet the demanding challenges of remote operation. RIEGL presents three new easy-to-use and intuitive mining apps that will support users in their daily work, especially in critical situations. Based on reliable real-time data, necessary decisions can be made promptly on a sound basis.

Winter Garden, FL – January 21, 2021 Remote Operation is the keyword of our time, even applying itself to the mining industry. The VZ-i Series of 3D terrestrial laser scanners are ready to meet the demanding challenges of remote operation. RIEGL presents three new easy-to-use and intuitive mining apps that will support users in their daily work, especially in critical situations. Based on reliable real-time data, necessary decisions can be made promptly on a sound basis.

RIEGL’s 3D terrestrial laser scanners can smoothly be integrated in any network infrastructure by using LAN, Wi-Fi, and LTE-interfaces, which enables fully remote operation of the scanners. With the installation of customized apps for automatic data acquisition and data processing, the user gets automatic real-time results without any user interaction.

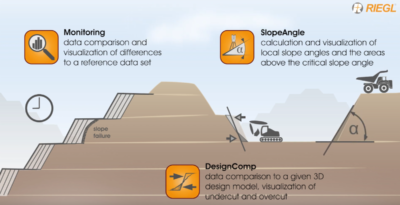

For applications in mining, RIEGL now presents three customized apps

For applications in mining, RIEGL now presents three customized apps

Thomas Gaisecker, RIEGL Manager Mining Business Division: “To optimize their work, the operators of mining machines need to get measurement results in real-time. Apps make this possible. The new RIEGL mining apps ensure that they get the data acquired by the scanner immediately as well as relevant, reliable and accurate deliverables to make prompt and appropriate decisions.”

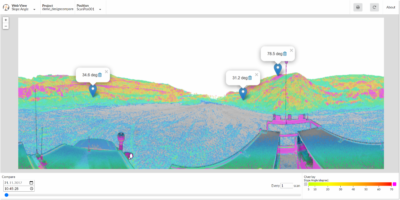

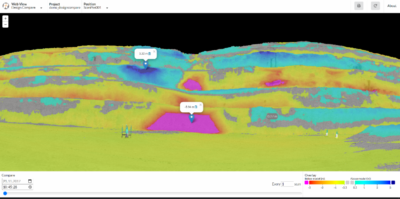

Fig. 1: Screenshot of the web browser interface: Critical slope-angles of more than 70° are highlighted in pink in this example. Markers can be set interactively to monitor these points over a time-series of scans.

RIEGL Slope Angle App

Using this app, slope angles are calculated automatically from scan data. Critical slope angles can be highlighted and sent to the user, e.g., the operator of loaders. The real-time information helps them to keep the slope angles of stockpiles and dump areas within the defined limits. They receive the information on a web browser on every device, which is connected to the mine network. No software installation or processing of the data is necessary. Everything is processed automatically within the app on the scanner.

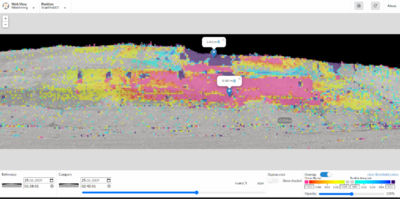

Fig. 2: Screenshot of the web browser interface: Threshold values and color tables can be set by the user absolutely flexible.

RIEGL Design Compare App

Using this app, overcut and undercut are calculated based on a given design model. While undercut is a waste of money, overcut can involves major safety risks. With the use of this app, the operation of heavy equipment such as digging machines can be optimized to streamline the mining process.

Fig. 3: Example slope failure area: By sliding through the timeline of acquired scans movement trends can be detected with enough lead time to evacuate the endangered areas before the slope failure take place.

RIEGL Monitoring App

Using this app, change detection can be calculated to a given reference scan. This allows to detect movements of e.g., highwalls long before it is visible to the human eye. The interpretation of the movements through a time series of scans allows the prediction of a possible slope failure. That can truly save lives! It ensures to have enough time to evacuate people and to remove machinery from the endangered areas.

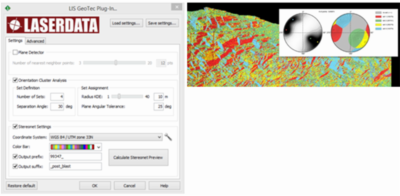

Additionally, RIEGL has further optimized their software packages RiSCAN PRO and RiMINING. The new LIS GeoTec Plugin enables geotechnical analysis of scan data by providing statistical tools within an easy-to-use graphical interface. Besides the calculation of dip-direction and dip-angle of rockfaces, it allows for the analysis of discontinuities by creating pole-plots and colorizing the scan-data by clusters of similar orientation. This gives specialists a better understanding of stability, joints, and faults of the analyzed rockfaces.

“We are ready for the mine of the future”, summarizes Thomas Gaisecker, RIEGL Manager Mining Business Division, “And what particularly distinguishes our hardware and firmware architecture is that it is open for developers. Using the provided RIEGL documentation every software programmer can develop his own apps written in Python programming language for the RIEGL VZ-i Series scanners.”

To explore these apps, the new video “Mining Apps for RIEGL VZ-i Laser Scanners” is available at the RIEGL Ultimate LiDAR YouTube Channel.

About RIEGL

RIEGL is an international leading provider of cutting edge technology in airborne, mobile, terrestrial, industrial and unmanned laser scanning solutions. RIEGL has been producing LiDAR systems commercially for over 40 years and focuses on pulsed time-of-flight laser radar technology in multiple wavelengths. RIEGL’s core Smart-Waveform technologies provide pure digital LiDAR signal processing, unique methodologies for resolving range ambiguities, multiple targets per laser shots, optimum distribution of measurements, calibrated amplitudes and reflectance estimates, as well as the seamless integration and calibration of systems. RIEGL’s various 3D scanners offer a wide array of performance characteristics and serve as a platform for continuing “Innovation in 3D” for the LiDAR industry. From the first inquiry, to purchase and integration of the system, as well as training and support, RIEGL maintains an outstanding history of reliability and support to their customers. Worldwide sales, training, support and services are delivered from RIEGL’s headquarters in Austria; main offices in the USA, Japan, China, Australia, Canada and UK; and a worldwide network of representatives.