Between October 14-17, RIEGL USA hosted their first North American Training Symposium in Orlando, Florida, an event aimed at bringing power users together for training and networking. RIEGL is known throughout the lidar community for first-rate meetings and attention to detail. With such a wide array of customers and technology under one roof, we caught up with Joshua France, Mobile Laser Scanning Segment Manager, to address a handful of recent developments…

*LM – Josh, thanks for taking time to catch up. We noticed that RIEGL attended the Railway Interchange event in Minneapolis. Are you seeing increased interest in lidar amongst railway operators?

Railway Interchange is a big show for the rail industry with a full outdoor yard portion along with a very full exhibit hall. Exhibits ranged from electronic switch mechanics to train engines so there were a lot of interesting sights and sounds.

RIEGL VMX attached to custom track cart.

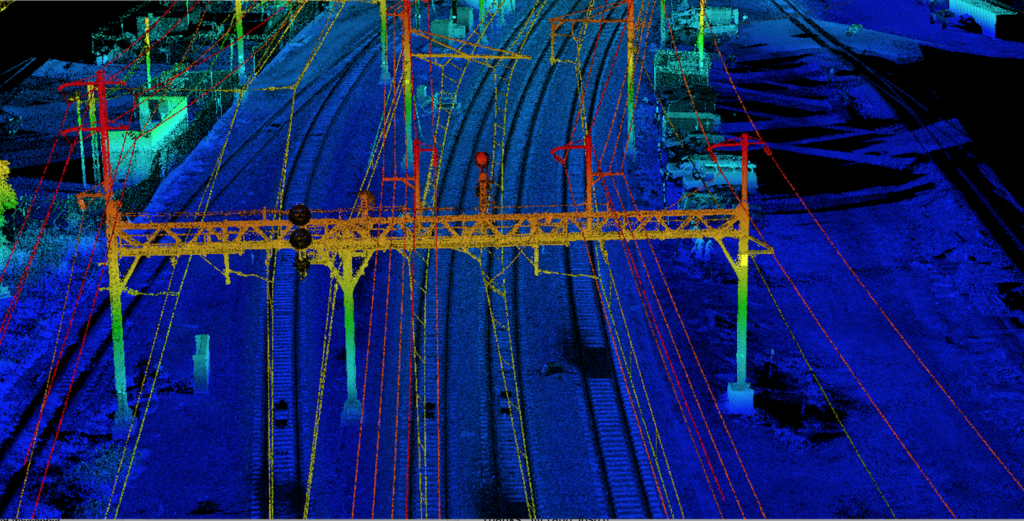

There has been quite a bit of lidar usage for railway updates, construction, and positive train control (PTC) over the past few years. Most of this lidar work has been done by our clients as contractors with the major railway operators known as class 1’s. There have also been many projects for light rail and city transit inspections and surveys such as the one presented on the LA Metro tunnel earlier this year.

Just like the rest of the geospatial industry, there is increased interest in a more complete information approach. Just recently, Amtrak sent out an RFP for a full lidar collection of their northeastern rail network. I expect this trend to continue and grow.

RIEGL has been a value provider of tunnel scanners for years to several key geometry car producers such as Plasser American. A geometry car has up to half a dozen instruments on it and takes profiles of the track to feed into a machine that helps adjust the tracks by either pulling or throwing the rail. This is called tamping and the machines are very impressive to watch while they work. They resemble giant insects crawling the length of the track and making very small adjustments to increase the alignment of the tracks, which allows the ride to be smoother and, in most cases, faster.

*Indeed, we’ve covered PTC in the magazine1. Who’s “doing things right”?

In the geomatics world, collection along the rail corridor is very challenging. There is limited time to do it and if you don’t get it on the first try, getting a second shot could be hours or even days away, due to tight train schedules and availability.

We have many clients doing great work on the rails and keeping lidar data on track to be viewed well within the industry. One key project was the work done by SSI on Penn Station in New York City last year. They were able to model the whole station and now their engineering partner, HNTB, is extracting full models of the tracks for exact manufacturing of the rails. This was a true “collect the data once and use it many times” example.

*Makes sense. Can you speak to how has RIEGL’s mobile platform has evolved in recent years?

Due to a user’s limited time on the rails and need for full data collection in one pass, we have developed a 3-scanner system called the VMX-RAIL. This allows for a full cross pattern on all surfaces to be collected and seen along the railways, which greatly helps with extraction and CAD modeling of both the rails and the buildings along the corridor, leaving no angle unseen. We released a new video for VMX-RAIL recently:

Yes and no. We have no problem collecting the data and processing the data with our software but now we must be able to share the data and the extracted features quickly and over mobile devices. We have been working with Esri and hope to have some new things to show in the next few months from our collaboration with them.

*So much has changed since you wrote about this initially2. The efforts with Esri are exciting—we’ll have an article about them in our next edition. Speaking of collaboration, you just wrapped the Training Symposium. How did it go?

The RIEGL North America Training Symposium was a great way to gather our users together and catch up on the latest and greatest training. It was a great way to revisit training information, touch on best practices, and showcase new features in our hardware and software. It was also a great way for our users to network with each other in the community and make new contacts with one another. Overall, it was a highly successful week and we’re already looking forward to our next one!

*Your new office(s) should be ready just in time! Thanks, Josh.

Over the summer, RIEGL announced plans for significant expansions of their European and U.S. headquarters. Both buildings are expected to be ready by the fall of 2020.

—

1: Using Hybrid LiDAR for Positive Train Control (PTC) Systems: James Wilder Young, Vol. 6, #2, 2016

2: “It’s About Time“: Joshua France, Vol. 4, #5, 2014