In the coming months, Hexagon will unveil the next-generation single-photon lidar (SPL) airborne sensor. An upgrade from our extremely popular Leica SPL100 wide-area elevation mapping system, the new product will incorporate the latest in SPL technologies with an eye towards significantly reducing the aerial collection costs associated with updating large terrain mapping projects, such as USGS’s remarkably ambitious and successful 3D Elevation Program (3DEP).

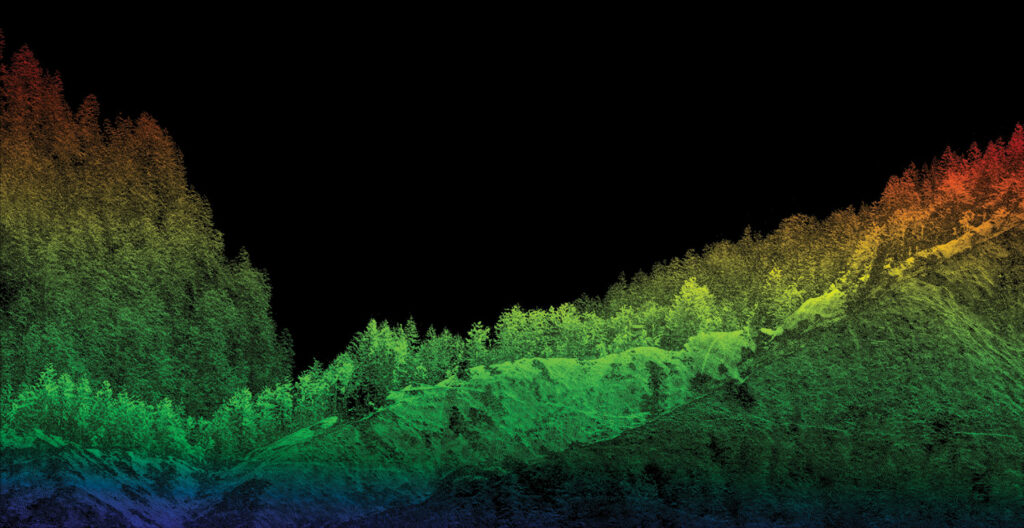

Elevation data captured in Switzerland with Leica TerrainMapper-3. Today, lidar can penetrate forest canopies to accurately measure tree height, canopy density, and ground elevation.

The commercial mapping industry in general is experiencing a period of exciting transformation, and the lidar segment of the market is growing as fast, or faster, than any other. Like many technologies, lidar’s evolution has been driven by a combination of breakthroughs in technical innovation and customers’ changing economic and end-user requirements.

To fully understand where lidar technology stands today, how far it has come in a short period of time, and where it is going, we thought it would be valuable to revisit the evolution of airborne laser scanners, now known as lidar, or light detection and ranging. This will also help differentiate current variations of systems that fall under the term ‘lidar’.

Laser profiling proves potential

The aerial technology we know today originated as ‘laser profiling’, carried out using helicopters equipped with laser range-finding devices. As the helicopter moved at a relatively slow speed compared to fixed-wing aircraft, the instrument onboard emitted laser pulses at a rate of about 1000 to 2000 per second in a single line toward the terrain below.

Introduced in 2002, the Leica ALS40 provided 45 kHz max pulse rate and 70 Hz max scan rate.

These pulses were reflected off the ground, returned to the sensor, and were translated to distance measurements with a simple time-of-flight calculation. Combined with the helicopter’s known altitude, each calculation was converted into an elevation measurement for a point on the Earth’s surface. The collected data created a narrow profile of the terrain due to the fact that the device only emitted light pulses in a single line as the helicopter traversed the landscape.

Laser profiling was very expensive, and its applications were limited to narrow corridor data collection, usually for energy utilities and pipeline operators. Otherwise, laser profiling was often relied upon to spot-check other elevation data sets, especially in photogrammetry. But the potential of the technique was obvious. Until then, most airborne terrain mapping was conducted with photogrammetric analysis of optical images, involving interpolation for the vast majority of surface points.

Not only did lasers directly and accurately measure points instead of estimating them, but the light pulses slipped between tree canopies, capturing elevations of the ground below – something image-derived photogrammetry could not do in densely vegetated areas. Post-processing analysis could be performed on the laser data to differentiate return pulses that had reflected off treetops and building structures from those that had struck the ground, thus generating true bare-earth digital elevation models.

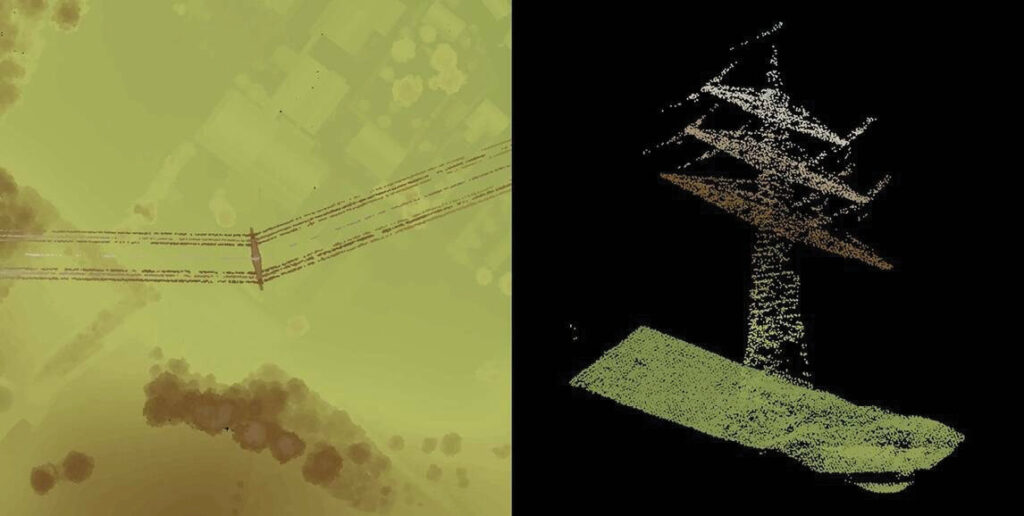

Data captured with single-photon lidar.

The next innovation revolutionized airborne laser profiling and transformed it into what could really be called laser mapping. A scanner was placed below the laser, so that the light pulses were scattered towards the surface in wide swaths instead of a single line, capturing terrain measurements across broad areas. Installing these new laser scanners in fixed-wing aircraft able to fly faster and higher greatly increased collection capacity and overall cost-effectiveness.

For lack of a better term, this early version of airborne laser scanning is often referred to as linear-mode lidar.

Airborne linear-mode lidar was increasingly viewed as a viable mapping technique. Accurate, bare-earth elevation models could now be made with point spacings of only a meter or two, even under vegetative canopies. Among the many initial applications of this technology was the creation of highly precise hydrographic maps that could be used to determine where surface water would flow in the event of flooding situations.

Two vital innovations, however, enabled lidar to take this gigantic leap forward in terms of accuracy and its widespread use by mapping organizations.

Enablers and drivers

The first was the introduction in the late 1990s of the GPS/Inertial Measurement Unit system, or GPS/IMU, onboard the aircraft. Simultaneous with capture of elevation points, this device collected precise coordinates of the aircraft’s location as well as its orientation (pitch and roll) in flight. During post-processing, this GPS/IMU data was combined with the lidar data to determine remarkably accurate X, Y, and Z coordinates for each elevation point.

The Leica TerrainMapper-3 linear-mode system combines a lidar unit and a camera system in a single pod. Its modular design allows for easy replacement, repair, or upgrade of individual components.

The second key enabler was the dawning of the digital era in mapping and remote sensing. Traditional photogrammetry was undergoing a shift from an analog process to a digital one thanks to softcopy photogrammetry. Shortly thereafter, digital airborne sensors were replacing film cameras for optical image capture. In a very short time span, the entire mapping process with remotely sensed imagery – from collection to output – had become digital.

For many long-established aerial mapping companies, this “greased the skids” for quick adoption of lidar. Because lidar was an inherently digital technology and airborne remote sensing was rapidly becoming the same, surveyors had already set up end-to-end digital processing workflows. The enormous digital lidar point clouds were not as intimidating as they might have been just a few years earlier, and the laser scanner was welcomed as a viable new source of map data.

Other factors fueled the growth of airborne lidar adoption in the late 1990s through the early 2000s. Several hardware companies, such as Optech (now Teledyne Geospatial) and Azimuth Corporation (acquired by Leica Geosystems in 2001), were manufacturing commercial airborne systems, and the competition was driving them to build more powerful units capable of making measurements at tighter point densities on the ground. Their systems could capture increasingly more accurate data at higher airspeeds and altitudes.

This market force-multiplier drove down product prices at the same time as flight operations became more cost-effective due to technical innovations.

The other market force spurring lidar adoption was customer demand. End-users of elevation data, especially in coastal areas like Louisiana in the US, where the modeling of complex tidal and flood-flow regimes depended on data accuracy and point density, were drawn to lidar. The interpolation of 3D values with optical imagery was not good enough, and geospatial end-users began asking for lidar technology by name in requests for proposals.

State and federal government agencies were instrumental in this. Although the 3DEP initiative did not officially begin until 2012 with the requirement for lidar use, USGS and other organizations were specifying its use for several years before then. Since then, national mapping agencies around the world have launched similar 3D programs that mandate lidar.

Drive toward simplicity

As competition drove airborne lidar to paint the Earth’s surface with a greater density of laser pulses while flying faster and higher, the laws of physics and the capabilities of linear-mode technology were being tested. To scale performance, systems incorporated multiple-pulse-in-the-air technologies, and later gateless multi-pulse capability, to allow overlapping pulses in flight – overcoming the limitations of the speed of light. With millions of overlapping pulses per second being emitted, the device had to keep track of them, which became extremely complicated, especially in cityscapes. Tall buildings, for example, caused some return pulses to reach the sensor before those emitted earlier, as well as other out-of-sequence challenges.

As a result, scaling up the performance of linear-mode lidar systems became excessively complex. The solution was to create massively parallel sensors, which single-photon and Geiger-mode lidar both represent.

In the case of the Leica SPL100, for example, the system essentially operates 100 linear-mode lidars operating at up to 100,000 pulses per second with very simple multi-pulse functionality, from which it is much easier to resolve correct range measurements in complex terrain. Geiger-mode employs a similar technique, but with a rotating scanner array operating as if it contains thousands of very simple single-pulse-in-the-air linear-mode devices.

These two variations may sound complicated, but are actually simpler because of the massively parallel design. The result has been that single-photon and Geiger-mode systems are easier to operate and maintain, while also achieving massive data collection rates over broad areas – even with extremely large variations in terrain elevations – with higher-speed aircraft.

While the overall accuracy of these systems currently approaches that of linear-mode, they capture over 10 times as much data in a flight hour, dramatically improving the overall cost-efficiency of airborne lidar. In other words, the recent evolution of airborne lidar systems has made it possible to measure a much higher density of elevation points on the ground over vastly larger geographic areas per flight at a much lower cost.

Self-driving cars drive innovation

Another key factor in this evolution, however, is the technological improvement in the lasers themselves. Laser range-finders are utilized in several very demanding industries, autonomous vehicles being the most notable. Manufacturers of self-driving cars have been scrambling to obtain lasers that are better, lighter, smaller, and cheaper than ever.

One challenge for laser manufacturers has always been developing systems that turn on and off very cleanly as each pulse is emitted. Otherwise, “jitter” or noise is introduced to the collected data sets, creating ambiguity and inaccuracy in the measurements. While linear-mode systems would measure a range over many hundreds or thousands of photon returns which would average out this laser jitter, in the single-photon case – as the name suggests – the range measurement is measured by one or two photons, so any jitter is immediately visible in the height accuracy. The developer of the laser unit incorporated into the single-photon systems today has significantly reduced the jitter in these products, with due acknowledgement to self-driving cars pushing the technology development rapidly.

At the same time, suppliers have been developing more lightweight lasers at lower price points to accommodate the automotive industry. In general, lasers can now capture high-quality data with less power, which means lower weight. This, in turn, has enabled lidar system suppliers to build more compact instruments that can be flown on smaller aircraft and even unmanned aerial vehicles (UAVs) – another leap forward for the mapping industry.

While the economics of aerial elevation mapping have been significantly enhanced over the past 25 years due to evolution in the basic technology and system design, the financial aspect has also benefited from a change in development philosophy. Leica Geosystems’ airborne lidar systems, for example, are designed with an upgrade path in mind. These products are built to incorporate at least two, or possibly three, next-generation overhauls before being replaced with new purchases.

Numerous other lidar improvements are in the works – driven by factors both inside and outside aerial mapping. On the the market now for 25 years, the technology shows no signs of slowing down—it’s still accelerating rapidly. In the next article, we will look at forthcoming changes that will accelerate airborne laser scanning well into the future.

Acknowledgement

This article will be published concurrently in LIDAR Magazine and the Hexagon magazine Reporter.