While multibeam sonar solutions have become an essential piece of seafloor and underwater mapping, the application of this technology has been somewhat limited. By and large, this technology integrates highly specialized tools requiring considerable expertise to implement.

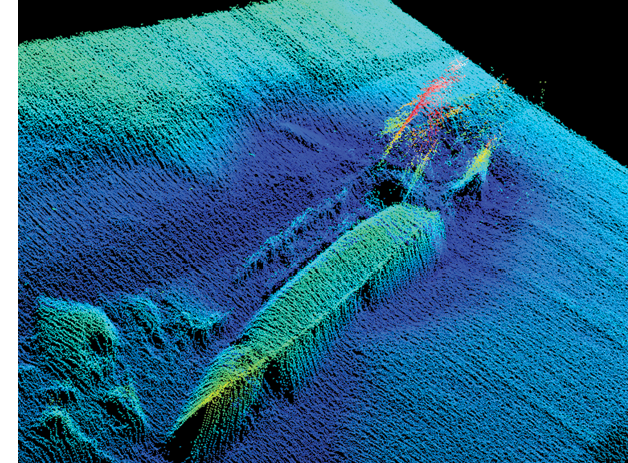

High-quality hydrographic data collection is achieved by integrating position and orientation data from the Applanix POS MV OceanMaster with Trimble RTX, alongside sonar data collected from a multibeam system.

The primary challenge to greater adoption lies in the complex array of integrated components, which demand a detailed understanding of the solutions and how they work together. An effective multibeam solution for seafloor mapping includes not just the multibeam sonar, but other pieces like positioning and orientation systems, laser and speed-of-sound sensors, and software to process and manage the data. These components must work together seamlessly to provide high-quality, accurate data in the underwater environment.

The required level of expertise in understanding these solutions, however, has changed considerably in recent years as technology providers are beginning to deliver more accessible, integrated solutions that prioritize data quality and usability, thus expanding the reach of this technology beyond its traditional hydrographic applications.

There is clear, significant progress towards realizing a multibeam sonar solution so intuitive and user-friendly that using it is as easy as operating a video camera: a tool where operators can immediately access and understand the data, without needing to delve into the technical complexities of configuring the system for the environment. While this idealistic vision of simplicity is closer to reality than ever before, current multibeam capabilities still require some considerable forethought to achieve the desired accuracy.

A POS perspective

The evolution of position and orientation systems (POS) provides some insights into the evolution of multibeam solutions. For example, Trimble® Applanix’s POS MV™ off-the-shelf commercial product is uniquely suited to the requirements of precision marine motion sensing, hydrographic surveying and charting. It delivers precise position, heading, attitude, heave and velocity data for a marine vessel and remote sensing equipment. By combining GNSS data with angular rate and acceleration derived from an inertial measurement unit (IMU), along with GNSS Azimuth Measurement System (GAMS) heading, it offers an accurate six-degrees-of-freedom positioning and orientation solution. When this is combined with multibeam sonar, hydrographers can generate very precise, georeferenced seafloor mapping data.

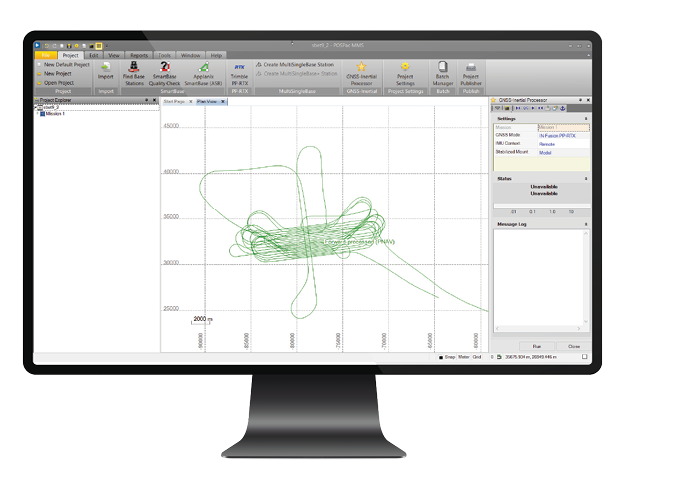

Typical marine vessel data processed in POSPac MMS PP-RTX mode.

Manufacturers such as Trimble Applanix have devoted considerable time helping customers integrate and configure system components at the factory and during commissioning. These tasks include understanding critical factors such as:

Timing – ensuring the timing of data from different sensors is properly synchronized

Datums – understanding the datums being used and how they need to align

Offsets – precisely measuring the physical offsets between sensors on the vessel

Misalignment angles – measuring and accounting for any angular misalignments between sensors

By resolving these factors and setting up the multibeam system prior to deployment, users can experience a more seamless flow of data across a fully integrated solution, thereby providing real-time or near real-time results so that hydrographers as well as marine contractors can quickly understand what’s happening under the surface without having a deep understanding of the system itself.

The key innovations on which developers have focused include improving data availability and quality through the deployment of a seamless GNSS solution that integrates sensor calibration and correction technologies with multibeam sonar.

A port of possibility

The Port of London project provides an example of this combined technology. The Port of London Authority is charged with ensuring navigational safety and port security along the River Thames, a complex survey area with a number of bridges, considerable river traffic and other obstructions that block GNSS line of sight.

Tasked with collecting survey data, the Port of London Hydrographic Service equipped its vessel with a POS MV OceanMaster GNSS-aided inertial navigation system for georeferencing the NORBIT multibeam sonar and a lidar sensor.

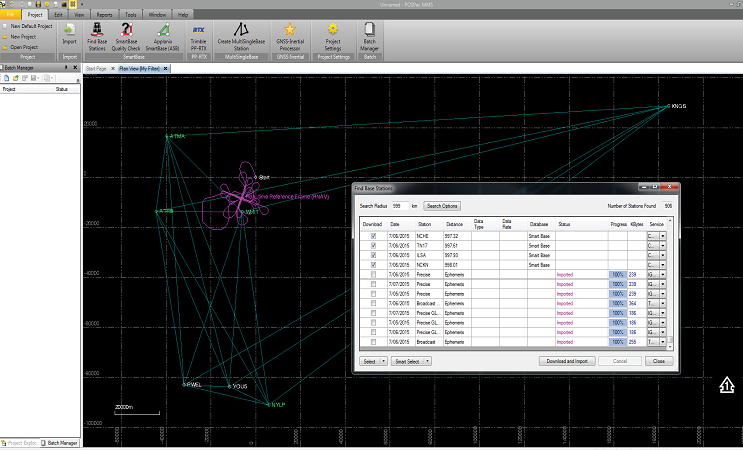

POSPac MMS includes a database of thousands of GNSS base stations worldwide, which can be automatically downloaded for single or SmartBase processing.

The survey team sought to demonstrate the performance improvements to be gained from the Trimble Applanix IN-Fusion+ technology for direct georeferencing of multibeam data. A comparison with previous techniques was undertaken, and the performance improvements were clear, especially in areas immediately around bridges.

With a fully integrated solution, the team was able to capture lidar and multibeam sensor data at the same time in order to map both the structural elements on the underside of a bridge and the underwater view, providing complete, accurate information in areas where the GNSS environment makes it most difficult to do so, but where, conversely, the need for accuracy is at its highest. Impressive results were obtained, with demonstrable improvements in mapping uncertainty.

On another project, PPP techniques provided centimeter accuracy independent of access to base stations. In this case, the Port of London Hydrographic Service collected data from the vessel Maplin, which is equipped with a POS MV OceanMaster GNSS-aided inertial navigation system for georeferencing the R2Sonic™ 2024 multibeam sonar. HYPACK™ software was used for data acquisition, and Fledermaus™, for the visualization of some results.

The data was collected in the Thames Estuary, where Ordnance Survey OSNet GNSS reference stations provide the data necessary to compute a SmartBase post-processed VRS network.

The Applanix SmartBase (ASB) technology allows the computation of position to centimeter accuracy, with distances to the nearest reference station on the order of 20-60 km. A comparison was then done between the ASB solution and that from PP-RTX. An area in the outer Thames Estuary provided an ideal location to compare the known accuracy of a SmartBase PPK solution with PP-RTX.

The PP-RTX post-processed approach achieved an impressive accuracy of 0.019 m, 0.021 m and 0.049 m RMSE in X, Y and Z respectively – and did so without using local reference stations. The PP-RTX post-processed approach provides a number of advantages including almost no convergence time and no need for local reference stations. The processed data is available within one hour after collection, which facilitates a fast turnaround of the mapping solution, ensuring deadlines can be met while providing reliable accuracy.

Inertial directions

For marine construction and asset-monitoring applications, surveys such as those undertaken by the Port of London provide a powerful modern approach to multibeam data gathering and ease of use.

Combining a real-time correction service or post-processing techniques with multibeam sonar allows surveyors and contractors to maintain the necessary data quality and accuracy for real-time construction applications such as monitoring dredging operations in challenging environments with limited sky visibility. One key is leveraging multiple technologies to ensure that the data remains usable and of high quality, even in obstructed construction sites and dredging areas, while ensuring the integration is seamless, simple and robust.

In the near future, complete multibeam solutions with more seamless integration of GNSS, inertial and other technologies such as lidar will make the technology more accessible to a wider audience, beyond just expert hydrographic surveyors, so that it can be applied to construction, environmental monitoring, search and rescue, and more. These cleaner, simpler, cloud-based, automated processing techniques makes hands-off and remote operations more attainable…a much needed workflow for the future.

Peter Stewart is director of marine products at Trimble Applanix. He is responsible for product development and the implementation of business strategies for the company’s marine solutions.

Peter Stewart is director of marine products at Trimble Applanix. He is responsible for product development and the implementation of business strategies for the company’s marine solutions.