Plan, fly, process, visualize. These four steps of the drone surveying workflow from Microdrones have guided professionals in fields like surveying, construction, and mining on the quest for quality deliverables. Often these deliverables can be delayed during the processing and visualization stage due to massive amounts of data, slow rendering speeds, and inadequate processing power. Furthermore, a lack of time, technical knowledge, or insufficient software can inhibit the workflow and prevent geospatial professionals from properly producing deliverables.

Microdrones, a world-class drone surveying equipment company, has made it easier than ever to complete data processing with affordable, cutting-edge software. The company’s integrated software, mdInfinity, helps users process data efficiently and affordably while saving time and converting data into actionable insights.

The mdLiDAR1000HR aaS: “HR” means high-resolution point clouds; increased coverage is made easier and more accessible than ever.

mdInfinity’s integrated system streamlines data processing

mdInfinity simplifies data processing with helpful modules that convert data into useful information. The software’s easy-to-use interface lets the user keep track of all data and seamlessly transform it through the integrated modules. Save processing time with batch processing and the option to save settings straight to the user’s profile. Base-station coordinates can even be saved in the software for easier setup when returning to the same location. mdInfinity’s convenient annual license gives the choice of receiving full access at any time to modules through the Unlimited plan or the flexible option to pay for what you need through the Pay-per-Project plan.

The mdInfinity suite is available in desktop and cloud versions, each containing distinct features and benefits to meet customers’ unique processing needs.

Customize the data processing

mdInfinity Desktop lets the user process and store data locally on desktop or laptop computers. This version works offline, so the user can do preliminary QC of data remotely in the field (an internet connection is required to download satellite correction data for trajectory processing).

With mdInfinity Cloud, data is processed and stored on secure virtual servers that safely provide storage and backup of all of projects. These state-of-the-art servers allow fast processing that delivers millions of points in minutes. Customers can reduce investment in processing hardware and storage with this practical back-end technology.

Data processing modules

Users can adjust and refine geospatial data according to their precise specifications with mdInfinity’s seven integrated modules. The specialized functions of each module fine-tune data while correcting issues from unforeseen factors like inclement weather. Users can conveniently manipulate data in the trajectory processing, georeferencing, precision enhancement, and boresight calibration modules from mdInfinity Desktop or Cloud. Data can be further processed by the Custom Service team using the strip adjustment, point-cloud direct colorization, and FORMap modules.

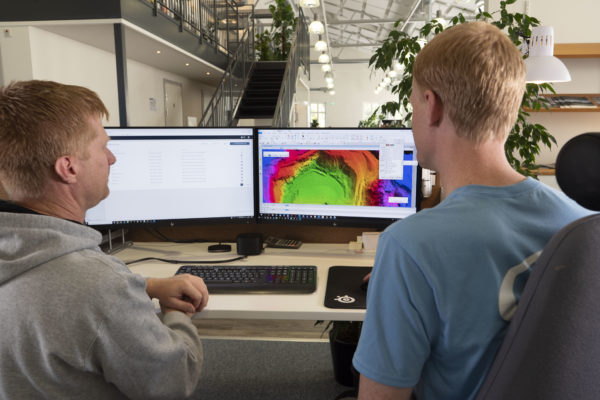

Using the mdInfinity software to transform raw survey data into actionable insights.

Trajectory Processing: get a more accurate position of the drone

The Trajectory Processing module provides a clear picture of a drone’s location at all times. Used for both lidar and photogrammetric solutions, trajectory processing merges raw GNSS data (with or without a base station) with the IMU data to yield a smooth trajectory file.

Photogrammetric data is processed by focusing on the location of trigger events while the trajectory for lidar data is estimated from the sensor’s location in 3D space at precise intervals. Users can export photogrammetric data as an exterior orientation (EO) file, ready to use in photogrammetric software to build orthomosaics. Lidar trajectory processing creates an sbet file which aids in the creation of an LAS point cloud in the next module, Georeferencing.

Georeferencing: merge raw and post-processed data to one point cloud

Georeferencing integrates the range and bearing angles of raw lidar data with the orientation and positioning of post-processed data to create an accurate 3D point cloud. With the specifications of the raw data, mdInfinity produces a georeferenced point cloud in geographic coordinates or in a local mapping frame specified by the user.

Raw data remains intact after the Georeferencing module is run, giving the user freedom to use other mdInfinity modules to transform the point cloud into the perfect end product.

Matt Rosenbalm, Microdrones sales manager for the southern US, appreciates how mdInfinity data modules make processing more efficient. “When it comes to georeferencing and trajectory processing,” Rosenbalm explains, “one of the big benefits of what Microdrones does is streamline the workflow, all through one suite of software, be it the cloud or the desktop version of mdInfinity. So, with Microdrones, we’re there to help you every step of the way from planning your mission, flying your mission, processing the data, and building your deliverables.”

Boresight Calibration: correcting boresight misalignment

When there’s misalignment between the IMU and the lidar sensor, the positions of lidar data points are greatly impacted. This module uses boresight calibration to help adjust points to their proper locations and stay within specifications . Users can improve the boresight calibration results by taking advantage of the boresight calibration mission flight plan offered through Microdrones mdCockpit flight planning software. This step is essential for precision jobs like surveying, construction, or mining.

Hanno Truter, Microdrones sales manager for Africa, says, “It’s extremely, extremely important to do a boresight calibration before each and every project that you take on.” He stresses, “Especially when surveying vertical faces in open pits, or open mines, if the boresight calibration is not correctly done or has not been done at all, a vertical face might not be in the correct position and that could influence volumetric calculations on a daily, monthly, or weekly basis.”

Modules like Boresight Calibration help provide an accurate view of the area in question, helping users properly complete projects. Users are recommended to benefit from added security by performing boresight calibration before and after a project to ensure that measurements are accurate.

Strip Adjustment: reinforce consistency between lidar survey strips

External factors such as navigation bias due to GNSS and/or IMU can affect initial results and create discrepancies between the strips collected. Even after completing a boresight calibration, it is possible to have a small shift between lidar strips. Should misalignments in the georeferenced point cloud still remain after a proper boresight correction, data should be refined in the Strip Adjustment module, available through mdInfinity Custom Services.

“Strip adjustment is all about consistency between flight lines,” explains Samuel Flick, Microdrones sales manager for southern Europe. “So, if you have a lidar mapping system, it helps you to optimize the measured translations and the angles between the strips and get a better matching of the data.”

Using an advanced optimization engine and a smart tie-point selector, positions and angles of the drone are adjusted in order to produce perfectly matched data. Instead of wasting time and resources having to recapture data, the user can deploy the Strip Adjustment module to correct any inaccuracies, leaving a more error-free dataset.

Precision Enhancement: remove outliers and reduce noise level

Precision Enhancement removes unnecessary outliers and reduces noise level while preserving integral edges and features in a point cloud. This powerful clean-up tool can pinpoint random noise and gross errors and then recalculate the points to produce an output point cloud at the same density.

Cleaning the flat surfaces found in the point cloud helps ground classification algorithms by reducing the impact of noise on the identification procedure. Without this software, manually removing outliers can take hours to process millions of data points.

Syamsul Bahri, Microdrones sales manager for Australasia, shares how the precision enhancement module makes all the difference in data processing, “When we view the data we can easily identify where the outliers are, delete these outliers automatically and recalculate the point cloud.”

Precision enhancement does the work in a fraction of the time with its ability to readily identify outliers and reduce the noise level by a factor close to 70%. The denoising capabilities of this module result in smoother surfaces and defined edges.

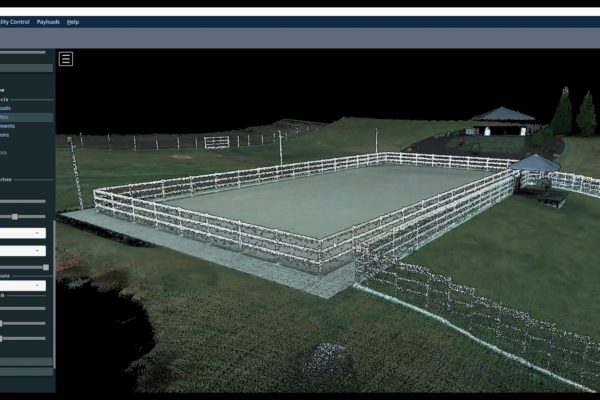

A screenshot from the mdInfinity data viewer of a point cloud created with the mdLiDAR1000HR aaS.

Point-Cloud Direct Colorization: add color for an authentic image

It is possible to give data a more realistic appearance without conducting a full-blown photogrammetric process. Point-cloud direct colorization, performed by mdInfinity Custom Services following generation of a lidar point cloud is based on the management of occlusions in the point cloud.

“Occlusions in the point cloud are colorized by considering only the relevant part of the point cloud,” says Irene Jimenez, Microdrones sales manager for south west Europe. “So, by directly colorizing the point cloud, a long photogrammetric process is really no longer necessary.” She goes on to explain the module’s efficient colorization process. “The point cloud is colorized with images that give the best values in contrast to colorization with an orthophoto. So a 2D image is placed on a 3D point cloud. Instead of black on colored holes, direct colorization allows us to get good data with a realistic colorization, even on steep walls and within a very short time.”

Occlusion management lets users see below a structure using the angle on an image, helping surveyors more effectively identify and distinguish their zones of interest. Requiring less side lap than a photogrammetric process, this module substantially increases survey speeds.

When homogenous surfaces are surveyed using an orthophoto, the image’s vertical points share the same color, sometimes causing a double imaging effect. The point colorization tool ensures that physical features retain their proper colors, better distinguishing a change in surface. A picture may be worth a thousand words, but a visual that can give accurate coordinates along with proper colorization is priceless.

FORMap: a faster approach to orthomosaics

When rapid results are demanded, FORMap (fast orthomap) implements a fast and comprehensive photogrammetric workflow to transform images and navigation data into an orthomosaic and dense point cloud.

Jimenez explains, “The main advantage of lidar is to get fast results. So the approach we took with photogrammetry is to produce fast results as well. FORMap is Microdrones’s fast photogrammetric workflow. It is made for jobs where the highest quality orthophoto is not needed, but greater efficiency and a gain of time is needed.”

Faster than many other photogrammetric software products, this Custom Services module boasts a 2-4 seconds per image response time, producing results minutes after a drone lands. With the advantage of being quick and easy to use, this module is best for surveyors who want fast images when an emergency strikes or simply when time is limited.

mdInfinity Custom Services

Customers who want to focus their efforts more on data acquisition and supporting their end-users can enlist the skilled mdInfinity Custom Services team take care of processing. This team of expert geomatic technicians will take users’ data and requests, and process according to project specifications. With a simple login, the user can submit data, provide instructions, and download results when ready.

Whether users prefers to utilize the user-friendly modules of mdInfinity’s integrated, customizable software, or leave the data processing to the Custom Services team, they have the power to choose the best route for producing top-notch professional projects.

Microdrones as a Service (mdaaS): affordable drone surveying

A user’s work and deliverables are unique — the process that produces those results should be unique too. When Microdrones as a service (mdaaS) is used, an easy three-step selection process helps choose the right integrated system, the type of payment for equipment, and the optimal plan for processing the data.

The user selects the surveying equipment to be used for data collection, then chooses to buy or rent the equipment. If rental is preferred, all maintenance and upgrades are conveniently handled by Microdrones. Finally, a payment scheme is chosen to fit user needs. Options include Pay-Per-Project using an online token system or Unlimited access to the modules with a monthly subscription.

mdaaS was designed to grow with the user’s business as projects and technology advance. Microdrones CEO Vivien Heriard-Dubreuil explains, “We developed mdaaS to propel the industry and expand the market from innovators and early adopters into the early majority phase of growth.”

Users need to have confidence in their work and the steps followed to reach their goals. They can enjoy versatility while paying for features as needed, accessing the best processing solutions as the client or project demands. The cost of ownership is built into the price upfront — it’s predictable, planned, and provided by Microdrones. Cash flow can be maximized through small monthly payments instead of one large payment. Thus it is possible always to have access to the latest, greatest technology as it rapidly advances, and never be left with something obsolete.

“We meet the customer where they want to be, in terms of options, choices, payment plans, and their preferences for maintenance, service, training, and support,” says vice president of global marketing for Microdrones, Mike Dziok. “What we’re really doing is making it easier for more surveyors to adopt this technology, via reasonably priced options in a subscription model. They can start enjoying the benefits right away.”

Unique project requirements don’t have to fit a standard framework. Microdrones has the tools and answers for developing a seamless, customized workflow, resulting in quality deliverables. with the company’s drone surveying equipment experts enable users to collect and process data the way that works best for them.