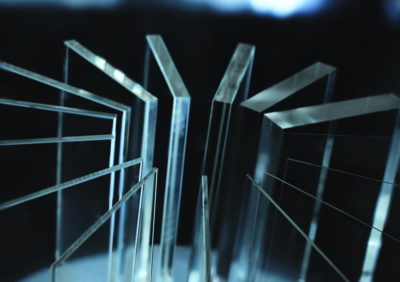

SCHOTT provides protective windows, optical components and hermetic packages and therefore the broadest portfolio of glass components for all relevant LiDAR technologies which are currently “in the race”: from mechanical spinning, MEMS scanning to flash and optical phased array (OPA). Photo: Schott AG

When it comes to autonomous driving, light detection and ranging (LiDAR) technologies are the foundation upon which a next-generation machine vision can be built. LiDAR sensors, together with radar and cameras, will be linked by artificial intelligence (AI) to enable the highest level of advanced driver assistance systems (ADAS 5) and allow for full automation of all driving functions. However, none of the existing LiDAR technologies on the market today meet the performance and reliability requirements to support fully autonomous driving at a competitive price level. SCHOTT is prepared to propel autonomous driving into the future with the broadest range of high quality glass components and hermetic packaging available to LiDAR manufacturers and suppliers at scale.

For LiDAR sensor systems BOROFLOAT® 33 glass enables protective windows with high transmission, excellent mechanical strength, outstanding thermal resistance and high chemical durability. Photo: SCHOTT

International technology group SCHOTT unveils a new approach to the supply of the burgeoning LiDAR market that emphasizes the broadest portfolio of glass material for the industry, combined with unmatched expertise and product consulting capabilities. SCHOTT’s high performance materials are a key component for manufacturers developing LiDAR technology – from protective windows to optical components and hermetic packages. “SCHOTT’s holistic approach in combination with customized solutions can significantly help to improve sensing technologies,” explains Boris Eichhorn, project leader for “LiDAR” at SCHOTT. “SCHOTT is therefore a reliable partner for advancing LiDAR technologies – e.g. mechanical spinning, MEMs scanning, flash and optical phased array (OPA).”

High-quality protective windows withstand harsh conditions

LiDAR systems need protection from rain, temperature fluctuations and impacts from gravel, rocks, and other debris. Specialty glasses are ideally suited as cover windows that protect sensitive components from the environment, especially compared to other transparent materials, e.g. polymers. However, strength is not the only factor. Protective windows must feature high transmission that allows near infrared (NIR) to pass through, while attenuating visible ambient light. Glass absorption filters RG850 have both; they are transparent in the NIR and opaque in the visible range.

LiDAR sensors that require protective windows with high transmission, excellent mechanical strength, outstanding thermal resistance and high chemical durability are best served by BOROFLOAT® 33 glass.

In addition, an anti-reflective (AR) coating with a hardness close to sapphire is proven to be very robust under harsh mechanical abrasion conditions for use in optics for UV, visible and infrared laser systems. LiDAR specific coatings that are optimized for NIR wavelength ranges are available for testing.

Filters, substrates and lenses – high performance for the optical path

At the base of a LiDAR system is usually a diode that receives the incoming laser light. Before light reaches it, it is redirected by mirrors or beamsplitters and must pass through filters so that only the desired wavelength is transmitted. High quality components are key in the optical path because the laser beam cannot afford to lose a single photon. Several of these components can be made of BOROFLOAT ® 33 glass, thanks to its exceptional high transmission and transparency for colorless visual appearance. With its superior temperature stability and excellent resistance to thermal shock, BOROFLOAT® 33 is ideal as a robust substrate for LiDAR mirrors, beam splitters and band-pass filters. D263® T eco glass – an especially thin LiDAR filter substrate – provides very high transparency across a wide range of applications. It is also suited for anodic bonding and chemical toughening. SCHOTT RG 80 glass is designed to filter the visible light and can be used as a substrate for narrow band-pass filters.

The properties of MEMpax® make it an excellent coating substrate that fulfils the requirements of MEMS mirrors. It matches with silicon in terms of thermal expansion and is well suited for anodic bonding.

LiDAR sensors must deliver long lasting good image quality regardless of temperature differences or aggressive climate conditions. High transmission and a thermal lens system design are commonly considered and SCHOTT offers a selection of high refractive index optical glasses. LiDAR sensors require superior overall imaging quality, while being compact and lightweight. Aspheric lenses in various sizes and materials meet these requirements perfectly. All lenses can be coated to specific custom designs.

Hermetic packages protect and power LiDAR sensors

SCHOTT hermetic packages can be used to protect laser diodes, photo diodes and MEMS mirrors against internal condensation and harsh external elements of the driving environment in all types of LiDAR sensor devices. SCHOTT offers LiDAR sensor providers and its component suppliers a collaborative partnership and solutions optimized for competitive, high-volume manufacturing. SCHOTT’s hermetic packaging technology is the trusted choice of world-leading automotive and optical module manufacturers.

SCHOTT offers different options when it comes to product size, shape, materials, technology, and all-round R&D support as well as solutions optimized for competitive, high-volume manufacturing. In packages for light sources of

LiDAR sensors, TEC (thermoelectric cooler) and copper header designs cool high-power lasers in order to maximize the optical power and control a constant wavelength. High-transmission glass and advanced designs enable excellent optical performance. Through hermetic packaging technology also the photo diodes can work properly and reliable. Packages for MEMS mirrors of LiDAR sensors allow for better MEMS performance because a vacuum-sealed hermetic environment is essential for optimal response speed and scanning performance. After mounting on printed circuit boards, they also offer better resistance to mechanical shock and vibration thanks to through-hole technology, miniaturized designs, and different shapes of packages that meet customer specifications.

SCHOTT has been a trusted supplier for decades thanks to its many years of experience in the automotive as well as the opto-electronic industry. Boris Eichhorn: “When it comes to autonomous driving, the LiDAR industry now finds in SCHOTT the broadest range of glass components and hermetic packages for LiDAR technologies as well as sophisticated know-how and support for their sensor challenges according to our claim “sensing your vision.”

About SCHOTT

SCHOTT is a leading international technology group in the areas of specialty glass, glass-ceramics and related high-tech materials. With over 130 years of experience, the company is an innovative partner to many industries, including the home appliance, pharma, electronics, optics, life sciences, automotive and aviation industries. SCHOTT has a global presence with production sites and sales offices in 34 countries. In the 2017/2018 fiscal year, the group generated sales of around $2.5 billion with over 15,500 employees.