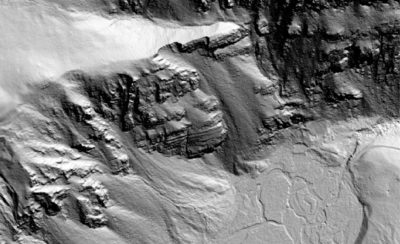

This digital elevation model (DEM) cross-section shows the many stratified layers within the Stillwater Complex in Montana.

Meeting the need for critical minerals, increasingly used in the production of a wide range of products in modern society, has never been a greater priority. Critical minerals are key components of personal high-tech devices, alternative energy solutions, national defense applications and so much more, making the demand for these minerals and their evasive supply a significant concern for the U.S. economy. Locating these minerals to reduce our reliance on imported minerals can be less labor intensive when using 21st-century tools such as lidar.

Critical minerals have become part of every day life. They are needed for the manufacture of touch screens in most electronics, computer chip production, weapons guidance systems, infrared optics and lasers, as well as in industry, agriculture, manufacturing and construction. Critical minerals are needed to produce batteries, jewelry, pharmaceuticals, health and beauty products, paint, fire-retardant materials, oil and gas products and many other materials.

In the U.S., more than 90 minerals are tracked and evaluated by the U.S. Geological Survey (USGS) Mineral Resources Program. Mineral resource potential, production, and consumption are monitored and, from this, some minerals are determined to be critical commodities; meaning, they have important uses, no viable substitutes and face potential disruption to the supply. Additionally, several more of these commodities, while not considered critical, are still important for many uses. According to recent data reported on the USGS Mineral Resources Program website, U.S. imports for mineral consumption are greater than 50%, with 100% dependency for many of them. Several critical minerals simply do not exist within the U.S. Furthermore, some countries possess a near monopoly on these resources, which could lead to supply disruption with economic impacts on a global scale.

This DEM cross-section of stratified layers within the Stillwater Complex highlights the value of the canopy penetration that lidar data produces.

Recently, a federal strategy was implemented to ensure a secure and reliable supply of critical minerals located within the U.S. A 2017 presidential executive order was issued to define critical mineral resources, increase private-sector domestic exploration for critical minerals and decrease the country’s dependency on critical mineral imports. With a goal of mitigating strategic vulnerability for the security and prosperity of the United States, this directive was issued to identify new sources of minerals and increase mineral production activity at all levels in a safe and environmentally responsible manner. As part of this executive order, access to and utilization of advanced topographic, geologic and geophysical data is essential.

To help accomplish those goals, continued discovery relies on a mixed approach, including but not limited to topographic lidar data, geologic mapping and geophysical techniques for exploration, such as aeromagnetic and radiometric measurement surveys. If improved topographic data is available,

it makes mineral exploration safer, more productive and more efficient, while providing methods of detecting alteration and mineralization patterns at the earth’s surface. Lidar provides high-accuracy data at a resolution that explorers searching for minerals in the past did not have.

Using lidar is like turning on the lights in a dimly lit room

Many of these critical mineral deposits are found in Western states, in areas that have not been mapped by high-resolution lidar or where the current mapping is outdated.

Using lidar as a tool in mineral exploration provides valuable options for increasing safety and efficiency. If improved topographic data is available, it makes mineral exploration safer, more productive and more efficient, while providing methods of detecting alteration and mineralization patterns at the earth’s surface. Lidar also provides source data for accurate base maps, surficial feature identification, soils interpretation, and identification of faults and fractures. The ability to accurately model the terrain and penetrate vegetation is a valuable resource for the detection of features that previously would have been much more difficult to observe.

The major import sources for mineral commodities upon which the U.S. is net import reliant, as of 2016. The U.S. Geological Survey

Mineral deposits have topographic signatures that provide clues to their location and content. This can be related to the way deposits weather or, in some cases, their resistance to weathering. Also, lidar can provide a detailed view of stratigraphic layers in exposed surfaces, which are key areas of investigation that can help geologists pinpoint areas for further exploration. These layers can be seen in the field or with imagery, but lidar enables analysis in a 3D environment before any field work is performed.

Soil analysis is another tool used to explore for mineralized rock, in particular, to understand how the soil in an area came to be in its current location. Is a soil sample on top of mineral-rich base material, or has it moved over time via glacial transport? Analysis of the lidar surface can help answer these questions by determining if mineral-rich material is underfoot or if it has moved over time, which may lead to identifying more suitable areas to further investigate.

The location of faults and fractures within the topography is critical information in the right hands. Offsets in igneous layering associated with mineralization can cause layers to shift, which when identified on the surface, provide additional evidence and guidance for assessing suitable exploration locations. Additionally, faults and fractures associated with drainage can be direct guides to mineral-rich ore. Understanding these features aids with assessing the integrity of the rocks. Furthermore, identifying water flow assists with protecting against landslides and unexpected water release into the mining areas, making mining sites safer.

All these factors play a part in developing a more efficient and safe operation. Without lidar, reaching similar conclusions would likely take place in the field and require significantly more boots-on-the-ground exploration. Accurate base maps derived from using the lidar data for initial site investigation can help mining experts carefully plan their work from the safety of an office environment, saving great amounts of time and energy.

Mapping Montana for platinum group elements

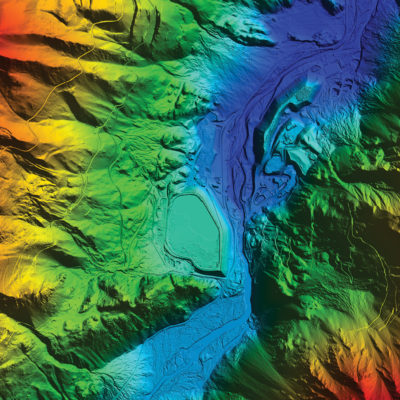

An example of how lidar can be used effectively in mineral exploration can be found in the Stillwater Complex project that Woolpert conducted in south-central Montana. The project was focused along the northern flank of the Beartooth Mountains, 75 miles southwest of Billings and 25 miles north of Yellowstone National Park. Most of the area lies within the Custer Gallatin National Forest.

Lidar can assist in the mining of critical minerals at sites such as this one in Montana’s Stillwater Complex.

The Stillwater Complex contains the most significant U.S. deposit of platinum group elements (PGEs), which are among the rarest metals in the earth’s crust. PGEs have a wide range of applications in industrial, chemical, manufacturing, electronic, health care, consumer goods and finance, but are only mined in a few places across the globe. Platinum is used in catalytic converters for vehicles, flat panel liquid crystal displays, and in the medical industry to develop implants and cancer-fighting drugs. The U.S. imports approximately 90% of PGEs, mostly from South Africa and Russia. This deficit, coupled with the tremendous importance of PGEs to the United States, lands them on the critical minerals list. Fortunately, lidar can help improve the mineral’s availability.

The Stillwater Complex deposit was discovered in the 1970s. Since the mid-1980s, a few hundred metric tons of platinum and palladium have been mined, but the Stillwater Complex could contain as much as 6,000 metric tons at depth. Those geological estimates indicate enough mineralized material to mine for decades.

Lidar became a valuable tool for the Stillwater Complex project because it offered the opportunity to view the many stratified layers in ways not possible prior to data acquisition. Subtle cross-cutting relationships within the layers require examination in three dimensions to better understand how the mineralized base material was formed and how best to locate PGEs for extraction. Additionally, the lidar data has allowed geologists to better understand glacial transport history within the complex as well as discover previously undetected faults and fractures hidden by vegetation.

Geologists have now been equipped with a tremendously useful dataset that can help transform their knowledge of the Stillwater Complex, resulting in a more efficient, accurate and safer plan for mineral extraction. Early results have proven highly successful. USGS geologists have underscored the utility of lidar to help extract such a valued resource by comparing it to exploring in a dark room and suddenly having the lights turned on. Early estimates of efficiency gains are on the order of turning what would be decades of work into merely a few years.

Lidar, along with complimentary remote sensing techniques, can help clear a path to becoming a more mineral-independent country. The lidar USGS has been collecting through its 3D Elevation Program (3DEP) has provided numerous benefits equating to significant return on investment. Utilizing 3DEP lidar to map our country’s critical mineral resources is yet another example of the importance of this program in helping our nation reduce dependence on foreign entities for these critical resources.

Sidebar:

Critical minerals include:

aluminum (bauxite), antimony, arsenic, barite, beryllium, bismuth, cesium, chromium, cobalt, fluorspar, gallium, germanium, graphite (natural), hafnium, helium, indium, lithium, magnesium, manganese, niobium, platinum group metals, potash, rare earth elements group, rhenium, rubidium, scandium, strontium, tantalum, tellurium, tin, titanium, tungsten, uranium, vanadium and zirconium.