Trimble Inpho Software Suite Extends Photogrammetric Deliverables for Broad Range of Geospatial Applications

Two New Capabilities Increase Flexibility for Photogrammetrists Generating Highly Accurate Deliverables

Trimble has announced a new version of its Inpho office software suite for photogrammetry. The suite includes two new capabilities:

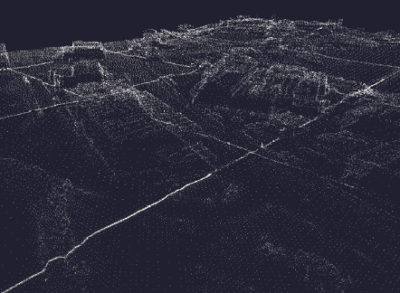

- MATCH-3DX software for the creation of rich 3D point clouds and true orthomosaics

- MATCH-3DX Meshing add-on for the generation of photorealistic textured meshes

The announcement was made at INTERGEO 2018, the world’s largest conference on geodesy, geoinformatics and land management.

Inpho version 9 combines the classical photogrammetric capabilities of the existing MATCH-T DSM product with modern 3D workflows. The addition of the new products, plus continued enhancements, further establishes Inpho as a comprehensive software suite available for the production of photogrammetric-based deliverables.

The new MATCH-3DX software incorporates state-of-the-art Semi Global Matching (SGM) techniques that enable photogrammetrists to reach a new level of quality and precision when generating large scale point clouds and true orthophotos from aerial (frame) images. Through the high resolution data sets, photogrammetrists can more clearly identify edges of surfaces, such as building corners and roof lines, enabling the extraction of highly precise measurements, CAD objects or Digital Surface Models (DSM). The new True Orthophoto capability ensures that each image pixel is directly related to the terrain height, simplifying mapping and the overlay of GIS data, especially for urban mapping applications.

With the new MATCH-3DX Meshing add-on, photogrammetrists can generate highly accurate, photorealistic textured meshes that enable non-professionals to easily navigate and understand the real world environment. The 3D textured meshes provide an efficient data type for use within industry leading GIS systems and web-based 3D visualization services—often used for 3D city modeling, construction simulation and gaming applications.

“Inpho version 9 combines both classical photogrammetric processing with new true orthos and photorealistic textured mesh deliverables, all in a single software environment,” said Tim Lemmon, marketing director of Trimble Geospatial. “Photogrammetrists can take advantage of the streamlined workflows and reduced training costs while having the ultimate flexibility to choose the workflow and deliverables best suited to their client’s needs.”

Trimble Inpho version 9 is expected to be available in fourth quarter of 2018 through Trimble’s Geospatial Distribution Partners. For more information, visit: trimble.com/Inpho.

Leica Geosystems Increases Efficiency with Hydrographic Survey Systems Upgrade

New Leica Chiroptera 4X, Leica HawkEye 4X save more than 50 per cent in flight costs

The higher point density allows customers to deliver high resolution products at reduced operational costs. Flight cost savings of 50 per cent can be achieved for typical bathymetric LiDAR end user specifications. The depth penetration increases up to 10 per cent with the new technology while not affecting the turbid water performance or accuracy.

Nova Scotia Community College is validating the new Chiroptera 4X bathymetric high-resolution technology in test projects on Canada’s east coast in turbid water conditions. “The four times increased resolution dramatically improves our ability to detect objects, even on the scale of features 1 metre by 1 metre where the increased number of points can be used to further clarify the objects location and details. For vegetation mapping, the increased resolution of the sensor provides us an unprecedented level of detail related to vegetation and other materials on the seafloor. We have also detected new seabed features not discovered from previous bathy LiDAR surveys in the same area, which indicates an increased sensitivity of the solution,” said Tim Webster, research scientist, Applied Geomatics Research Group (AGRG) Centre of Geographic Sciences (COGS), Nova Scotia Community College.

The 4X technology is available as an upgrade package to all current Chiroptera II and HawkEye III customers and will be integrated in all new bathymetric LiDAR systems. The improved resolution, depth penetration and accuracy provide substantial benefit for environmental and coastal monitoring, inland waters mapping, infrastructure planning, and near-shore applications.

Maximising efficiency

Typical end user specifications require two to four points per square metre for the highest quality level shallow bathymetric LiDAR data. This is easily achieved with a single flight line with the new Chiroptera 4X or HawkEye 4X shallow channel, while in previous generation double coverage was needed. This improvement saves half of the flight costs alone.

With the depth penetration of 2.7/k and collection of 140,000 points per second of the Chiroptera or HawkEye shallow channel, the new 4X technology offers an unmatched shallow water performance in respect to point density, turbid water performance and depth penetration. For the HawkEye deep channel, the 40,000 points per second collection is market leading in the industry and can easily deliver IHO order 1B data from single flight line.

“Optimising a bathymetric LiDAR system has always been a trade-off between sensitivity (depth penetration) and resolution. Our new 4X high-resolution technology allows us to improve both those parameters without any tradeoffs,” said Anders Ekelund, Hexagon’s Geospatial Content Solutions vice-president of Airborne Bathymetric LiDAR. “Performing advanced high-density site surveying allows users to extract better details for both above-water and underwater features, increasing our knowledge of coastal and inland waterways and habitats.”

For more information, please visit: leica-geosystems.com/products/airborne-systems/bathymetric-lidar-sensors

Comparison of LiDAR derived automated submerged aquatic vegetation mapping.

Kaarta Announces Stencil 2 Mobile Mapping System

Raising the bar for rapid, high fidelity 3D capture and processing

Frankfurt, Germany | Intergeo—Kaarta, innovator of real-time 3D reality capture, today announced Stencil® 2, the next generation of its popular real-time, high fidelity 3D mobile scanning and generation system. Stencil 2 improves mapping accuracy and workflow with a new User Interface, GNSS localization, upgraded hardware, Confidence Metrics, and enhanced software intelligence.

Stencil 2 makes real-time operation easy, organized, and intuitive with a new user interface and on-screen keyboard giving users better control over scanning operations, parameter input, and file management. Stencil 2 ships with an iPad tablet to access operations and view real time scanning on the fly.

Stencil 2 records GNSS data for use in loop closure to georegister and geolocate datasets, correcting for drift and further improving the fidelity of large area scans. Kaarta offers an optional GNSS Kit with Emlid Reach RS+ RTK GNSS receiver and custom mounting bracket. Alternatively, Stencil 2 integrates with other NMEA 0183-compliant GNSS systems.

Three passes through an intersection correctly registered in post processing using GNSS in loop closure.

A host of Stencil 2 hardware upgrades include a faster processor, full size HDMI connector for a more robust connection to monitors, and double the on-board storage capacity providing storage for more scans and reducing the need to frequently offload files.

At the heart of Stencil 2 is Kaarta Engine, Kaarta’s patent-pending advanced 3D mapping and localization algorithms. Kaarta Engine’s proprietary approach reduces the drift error of alternative SLAM systems by an order of magnitude.

Confidence Metrics provide immediate feedback on the quality of scans by signaling whether new scan data is registered properly in the existing map, estimating the likelihood of errors and allowing the user to increase the level of confidence by adjusting data collection techniques or adjusting parameters.

GNSS in loop closure: GNSS data showing dropouts over the course of the data collection [top], trajectory data from Stencil 2 with some drift [middle], and corrected trajectory in yellow overlaid on the original GNSS data [bottom]

Stencil 2 accurately maps exterior and large interior environments quickly and easily with a range of up to 100 meters and a data rate of 300,000 points per second up to 10Hz. Kaarta’s integrated 3D mapping and real-time position estimation allow capabilities not possible with fixed-base scanning systems. Stencil 2 further solidifies the feasibility of mobile mapping as a stand-alone solution while also widening the possibilities of using mobile mapping to complement or augment other scanning methods.

Stencil 2’s ease of use, breadth of applications, and streamlined workflow make it the perfect choice for infrastructure inspectors, surveyors, engineers, architects, facilities planners, security personnel, or anyone who needs an easy way to document the 3D world quickly and dependably.

Stencil 2 is now shipping worldwide. Upgrade packages are available to current Stencil owners.

Quanergy Selected as Exclusive LiDAR Partner for VRCO

LiDAR manufacturer to provide S3 solid state LiDAR sensors to enhance safety of land, air, and water capable NeoXcraft XP2

The NeoXcraft XP2, which VRCO and the University of Derby unveiled in late 2017 and intend to launch in 2020, is a two-passenger e-VTOL high-speed land, air, and water capable craft. The craft can scan and memorize take-off locations and store the data for use on the next approach to the same location. Quanergy’s innovative S3 solid state LiDAR sensor will be used for downward and forward scanning to enhance the craft’s safety, providing the NeoXcraft with the ability to detect, sense, and avoid objects upon takeoff, approach and landing.

“VRCO is pleased with the support from Quanergy, and the use of the S3 LiDAR sensor provides a new level of enhanced safety for the NeoXcraft,” said Michael Smith, chairman of VRCO. “Moving forward, all NeoXcraft will feature the S3 sensors as standard.”

“As the autonomous vehicle industry continues to evolve, it is imperative that all types of vehicles be equipped with technology that will give them the necessary level of awareness to keep passengers safe whether they are on the road or in the air,” said Dr. Louay Eldada, CEO and co-founder of Quanergy. “Our S3 solid state LiDAR sensor will give the NeoXcraft the ability to accurately sense and perceive its surroundings while seamlessly integrating into the design of the craft.”

In addition to its technical achievements, the compact design of the S3 enables the sensor to be concealed in the body of the NeoXcraft. This allows for real-time 3D mapping and object detection, tracking and classification, without compromising the aesthetics or aerodynamics of the craft.

To learn more about Quanergy’s S3 solid state sensors, please visit go.quanergy.com/e/297232/s3-/bx86n/207604617.

FARO and STORMBEE Partner to Optimize Traceable Construction

Breakthrough Wide Area 3D Scanning Solution

Enhanced Productivity

The FARO—STORMBEE airborne solution enables wide area scanning missions, such as highway or train infrastructure, large construction sites and buildings as well as open pit mines. While these would take days when scanned from the ground, they can now be completed in just hours without interrupting traffic on in process construction work. Additionally, this airborne solution further enhances productivity by allowing users to capture complex environments, such as factories, chemical plants or other infrastructure features inaccessible to ground based scanning, from the air with exceptional levels of accuracy and detail and create as-built drawings, isometrics and facilitate analysis. The data can then download to FARO BuildIT Construction software to monitor construction quality control and progress or to easily create as-built CAD models with FARO As-Built Suite.

Optimized Resource Deployment

The user-friendly BEEFLEX software allows users to create centimeter level accurate point clouds directly from the in-flight data. Furthermore, the intuitive user interface assures that just about anyone can become a viable “expert” with no more than one hour of hands on training. Finally, BEEFLEX data can be exported directly into FARO SCENE software for further analysis and/or to combine aerial scans with the detail rich data from terrestrial scanners.

“STORMBEE has developed and validated its UAV credibility from real life testing in the most rigorous environments” explains Liesbeth Buyck, CEO of STORMBEE“. As a result, we are confident that this turnkey solution, that includes the STORMBEE UAV and the FARO Focus laser scanner, creates a new reliability and quality benchmark for airborne 3D data capture solutions”.

“FARO pioneered the Traceable ConstructionTM end to end value concept and continues to innovate the construction industry by optimizing end user experience and value”, states Andreas Gerster Vice President FARO Construction BIM. “With the combination of the unique competencies of FARO and STORMBEE, we are now able to drive a new level of time and cost effectiveness for wide area 3D data capture for large construction projects or projects where terrestrial based scanning is not the most viable option”.

For more information: constructionbim.faro.com/en/traceable-construction/on-site-capture/

Creaform’s Pipecheck Software Brings Surface Corrosion Assessment to Full Pipe Joints

New Pipecheck 5.0 offers faster analyses and reports for pipes of up to 60 ft

Enhanced weld to weld inspections:

- Full-pipe joint assessment of up to 60-foot pipes: Surface inspection of industry–standard pipe joints up to 56 inches in diameter.

- Faster analysis and reporting: On-site analysis and reporting up to 6 times faster.

- Enhanced workflow: Data analysis is performed in sections and analyzed together to produce a single comprehensive final report, so pipeline owners have crucial information they need to act quickly.

- Multiscanner capability: Divide inspection time by the number of scanners used to ensure faster total inspection time.

- Other key competitive advantages of the Pipecheck solution include reliable and repeatable measurements that are independent of the operator’s or the technician’s skills.

A Game Changer in Pipelines Surface Inspections

“The challenge wasn’t only to increase Pipecheck’s capability as far as pipe lengths, but also to improve the speed of the analysis and reporting, regardless of a pipe’s size,” says Steeves Roy, Creaform Product Manager. “With no compromise on the speed of data processing, analytics, and reporting, Pipecheck 5.0 now becomes the most trusted full-pipe joint assessment solution on the market. All Pipecheck license owners already in the field and covered by the Creaform Customer Care Program will benefit from this major software upgrade.”

“Most asset owners and NDT service companies are turning to Pipecheck for pipeline corrosion mapping and assessment. What is key for our customers is the accuracy and repeatability of 3D mapping compared with manual measurements, as customers need to make the safest decision regarding a pipeline’s integrity,” adds Mathieu Magnan, Business Development Manager at Creaform. “Inspections that used to take days can now be performed in only a few hours with direct on-site reporting using Creaform technologies. With Pipecheck 5.0, it is now possible to scan, analyze, and report data from a full pipe joint in less than a day. This is a major performance leap forward compared with previous versions of the software.”

Project Update: World’s First 3D Printed Steel Bridge

Amsterdam based startup MX3D has finalized its 3D printed steel bridge. The project is still ongoing, the smart bridge project (with stability tests) will last over the next 2 years. For this they will regularly use the FARO Laser Scanner and BuildIT Construction software.

The Bridge, designed by Joris Laarman Lab, with Arup as lead engineering partner is now ready to be installed at its final location, but will first be on display at the Dutch Design Week (DDW) in Eindhoven, from October 20th till 28th 2018.

In addition to its unique construction, the bridge is also a living laboratory for data scientists. It is instrumented by Autodesk, Force Technology, Imperial College London, Lenovo & HBM with an innovative sensor network. Data obtained from the sensors visualize intelligence about bridge traffic, structural integrity, and the surrounding neighborhood and environment. During the DDW visitors are invited to walk over the bridge to generate the first data set. Data from the bridge will be used by partners like The Alan Turing Institute, the UK’s national institute for data science and artificial intelligence, along with Autodesk to build a digital twin model and sensor network which use advanced data analysis to monitor the bridge’s performance in real-time. The work on this 3D printed bridge will contribute to the future of safe, efficient and data-driven engineering by monitoring the structure as thousands of people and bicycles traverse the bridge hourly once in place.

Arup, the project’s Lead Engineer, and researchers from The Alan Turing’s Data Centric Engineering Programme (a consortium of researchers from Imperial College London and the University of Cambridge) have performed a successful load test of 10+ ton this September. Comparisons between predictions from computer models that the team have developed with the results from this test will be made to demonstrate the load carrying capacity of the bridge and provide invaluable structural performance data.

SMART BRIDGE

The consortium of mathematicians from The Alan Turing Institute have teamed up with MX3D to deploy a smart sensor network to develop a new data centric engineering approach for 3D printed structures. Arup, Imperial College, Autodesk and Force Technologies are actively involved in the design, install and use of the sensors network.

These sensors will collect structural measurements such as strain, rotation, load, displacement and vibration, and will measure environmental factors such as air quality and temperature, enabling engineers to measure the bridge’s health in real time and monitor how it changes over its lifespan. This data will also allow us to “teach” the bridge to understand what is happening on it, how many people are crossing it and how quickly.

The data from the sensors will be used as input for a ‘digital twin’ of the bridge, a living computer model that will reflect the physical bridge with growing accuracy in real time as the data comes in. The performance and behaviour of the physical bridge can be tested against its digital twin, which will provide valuable insights to inform designs for future 3D printed metallic structures and ensures it is safe for pedestrians under all conditions.

Pivots

Like all innovative projects the MX3D bridge project required several pivots. The initial design for the 12 meter metre bridge has changed significantly. Based on material research and structural testing Arup and Joris Laarman Lab created a structural design strategy. This led to the final bridge design by Joris Laarman Lab in early 2017.

In March 2017, the printing and assembly of large segments of the bridge began. In parallel MX3D engineers have continued working on realizing their vision of robots autonomously 3D-printing infrastructure. Last summer, a robot was placed on the bridge. It validated the company’s vision and confirmed that robots will be able to print bridges without human intervention.

FACTSHEET

Location Bridge: Oudezijds Achterburgwal, at the crossing with the Stoofsteeg located in the Red Light District of Amsterdam.

Technology: MX3D, Proprietary Software

Client: City of Amsterdam

Designer: Joris Laarman Lab

Lead Structural Engineer: Arup

Material & Structural Analysis: Imperial College London

Material Expert: ArcelorMittal

Research: AMS-3D Building Fieldlab, Amsterdam Institute for Advanced Metropolitan Solutions

Digital Tools: Autodesk

Digital Twin: Alan Turing Institute

Sensor Network Design & Install: Force Technology & Autodesk

Scanning: Faro Technologies

Construction Expert: Heijmans & Mous

Hardware, computing: Lenovo

Hardware, robotics: ABB

Hardware, Sensor Network: HBM

Hardware, welding: Oerlikon

Hardware, air cleaning: Plymovent

Welding Gas: Air Liquide

Material: Stainless Steel

Length: 12.2 meter

Width: 6.3 meter

Height: 2.1 meter

HxGN Content Program is Now Available Through GSA

Federal, state, local government agencies can now purchase high-resolution aerial

imagery directly through GSA

Hexagon announces HxGN Content Program imagery is now available directly through the General Services Administration (GSA). Imagery, such as this aerial capture of the Capitol Building in Washington, D.C., USA, can be downloaded or streamed for purchase from GSA.

Hexagon’s Geosystems Division, the smart digital realities provider, announced today the HxGN Content Program’s imagery is now available to government agencies directly through the General Services Administration (GSA).

Government agencies at the federal, state or local levels can now purchase high-quality aerial imagery content via subscriptions to a streaming service or physical pixel delivery for download. The imagery content is available directly in the application of choice through Open Geospatial Consortium (OGS), Web Map Services (WMS) and Web Map Tile Service (WMTS) protocols. The professional four-band (RGBN) orthorectified 15- and 30-centimetre imagery content meets conventional mapping accuracy requirements enabling use in many applications that in the past were only serviced by contracting for such products.

“Enabling our government customers to purchase directly through GSA offers a fast, flexible and cost-effective procurement solution to meet operational challenges,“ said John Welter, Hexagon’s Geospatial Content Solutions president. “With a significant increase in demand and continual refresh of the imagery content, we wanted to ensure it was easily available through our new offering with GSA.”

Quality control by experts

Launched in June 2014, the HxGN Content Program provides valuable geospatial content and delivers professional-grade airborne images captured with Leica Geosystems’ airborne sensors, including enhanced-resolution, four-band orthos and stereo imagery. The imagery data is processed by experienced photogrammetry professionals using the latest processing technology to meet conventional mapping standards and deliver an exceptional

product. Independent quality control is then performed to ensure accuracy specifications are achieved.

The imagery content is refreshed on a regular schedule of no more than two years, and data capture of entire states is done within one flying season. Current coverage includes the entire continental U.S., Puerto Rico, and portions of Canada and Europe.

To view the most current status of the HxGN Content Program’s data availability and acquisition, please visit hxgncontent.com and follow us @HxGNContent.

A full list of HxGN Content Program ortho-rectified aerials are available through GSA at gsaadvantage.gov/advantage/s/search.do?q=0:2HXIP&db=0&searchType=0